Specifications:

100% Brand new and high quality

Color: Silver + White

Material: Aluminum + Copper + PVC

Nozzle Material: Stainless Steel

Feed Type: Gravity Feed

Application: Paint Spray Gun

Type: LVLP(Low Volume Low Pressure)

Power Type: Pneumatic

Nozzle Diameter: 1.3mm,1.4mm, 1.5mm,1.7mm, 2.0mm

Spraying Distance: 200mm

Pattern width:180-280mm(7.0”-10.9”)

Air Consumption: 85-110 L/min(3.5-3.9cfm)

Fluid Output:140-190ml/minute

Working Pressure: 2-3.5bar(28.8-51psi)

Max.pressure of air:8.3bar(120.5psi)

Cup Capacity: 600ml

Applicable compressor:5gallon (20L) or more

Size of Spray Gun:16*18cm

Size of Cup:10*15.7cm

Inlet Interface: Standard 1/4″-19″ BSP/NPT Thread

Package Size: 22.6*14.8*12.3cm

Weight: 1kg

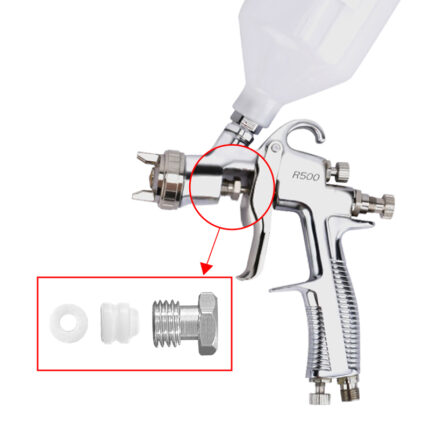

Adapter Thread Size: Internal Thread M16x1.5

Uses:Small-area spraying and layer defect repair treatment for household appliances, furniture, iron plates, aluminum, plastic parts, wooden plates, thin plates, decorative plates, solid wood furniture, denim clothing, etc., to obtain a good coating edge effect

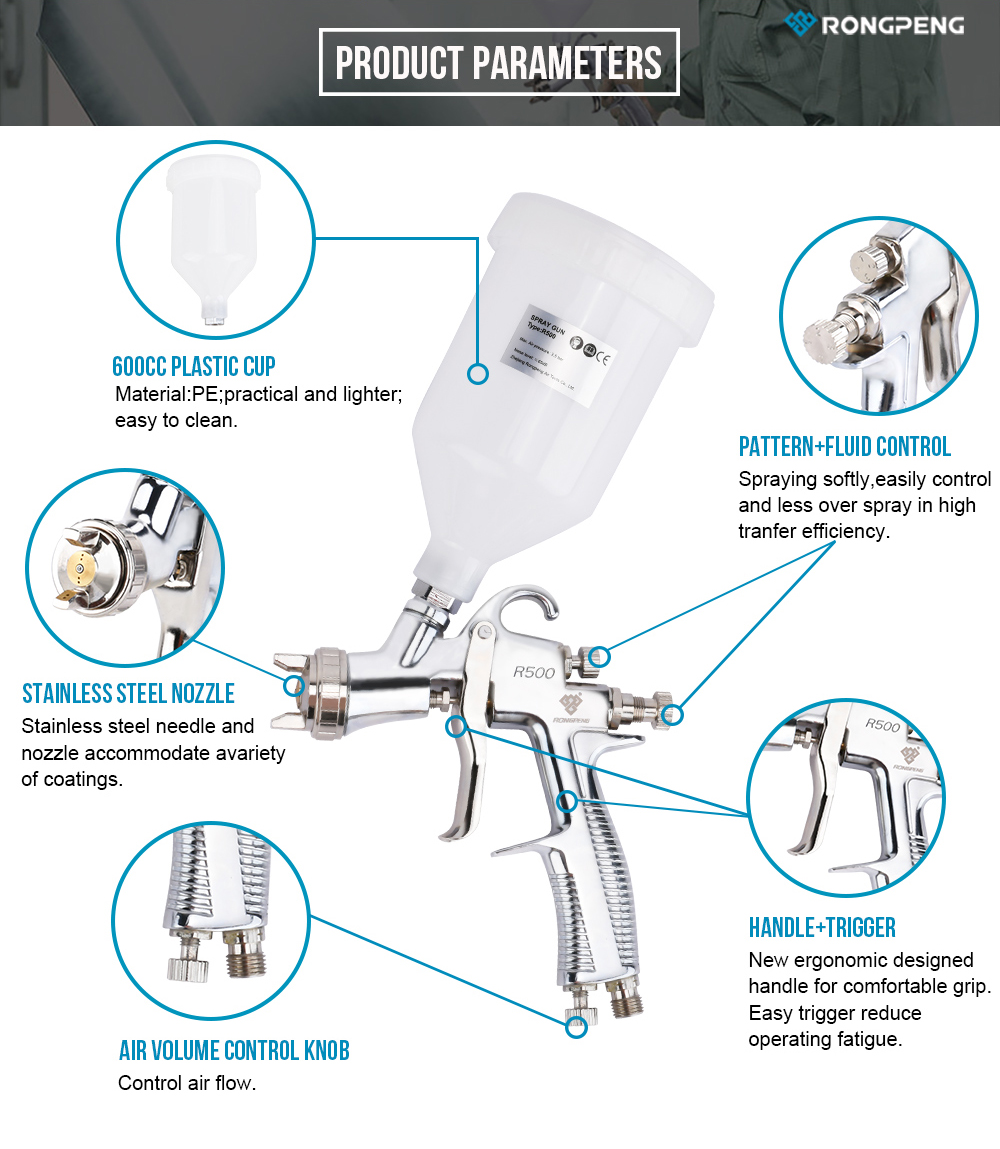

Product advantages:

1. The surface of the gun body is electroplated with nickel and chromium, which is beautiful in appearance and bright as a mirror

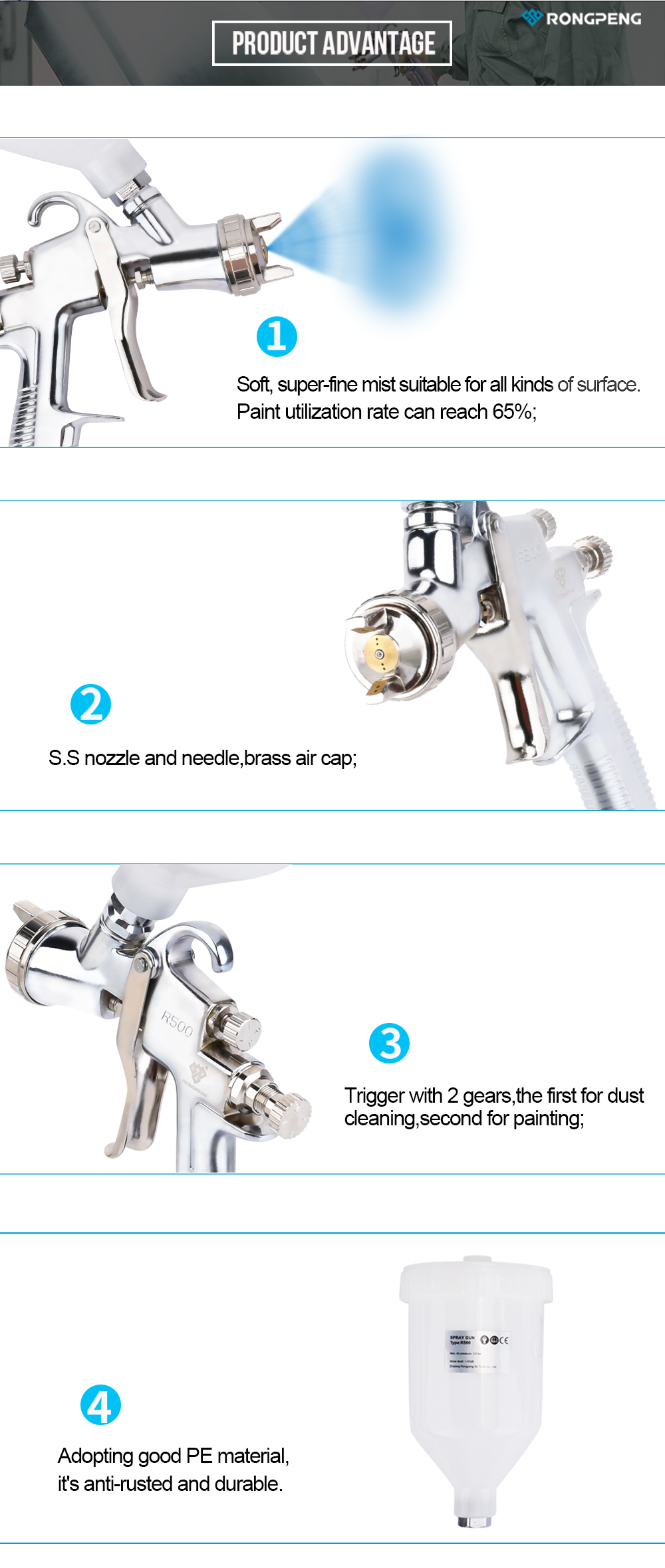

2. Modified high atomization gas path design, fine and fine atomization

3. Detachable, high-strength, wear-resistant and corrosion-resistant nozzle, long service life

4. High hardness stainless steel + copper combination needle, wear resistance, corrosion resistance

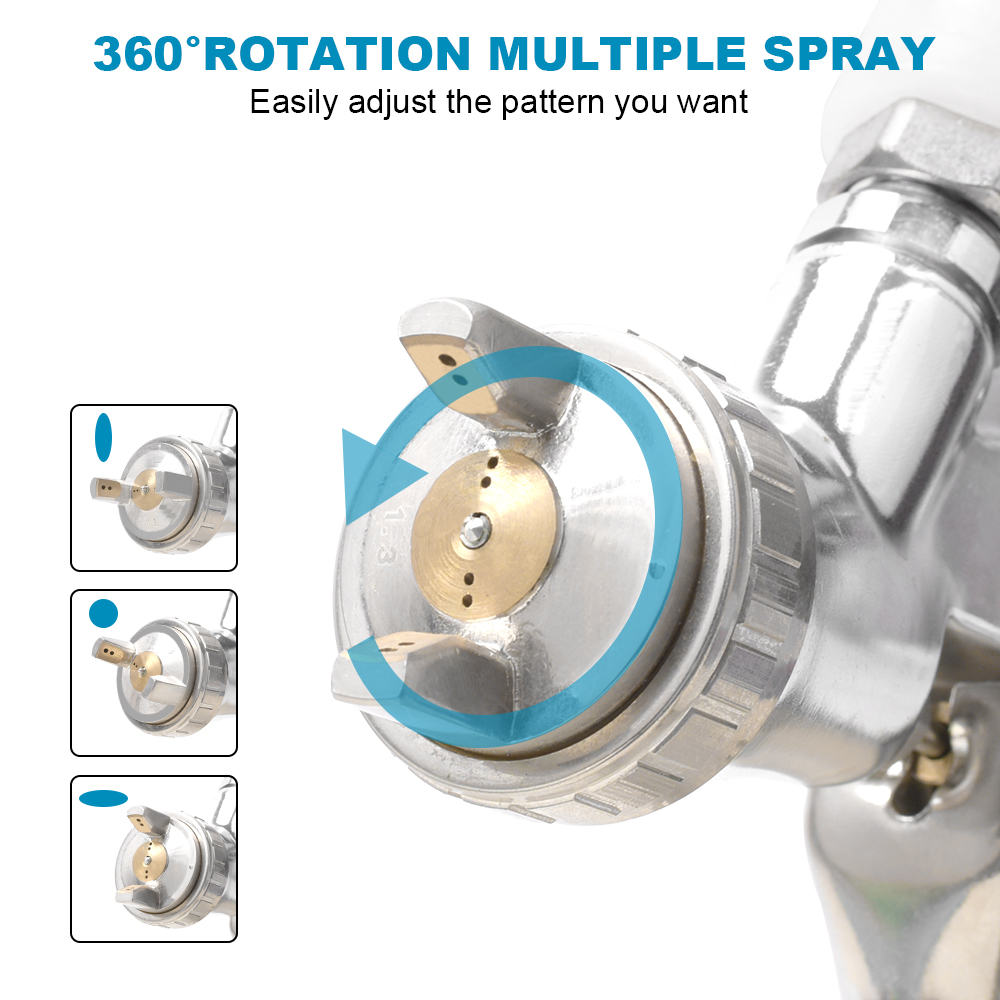

5. Precision lathe processing, pure copper production 360 degrees can easily adjust the air flow cap

6. The valve needle valve group, stainless steel spring combination, when adjusting the pressure, the knob is easy and flexible

7. Amplitude needle valve group, stainless steel material selection and stainless steel spring combination, the knob is easy and flexible when adjusting the spray width length, short, and round shape

8. The nozzle and the combined material needle are perfectly matched, with good sealing performance and no dripping.

Note:

1. Choose clean compressed air

2. Choose the spraying equipment suitable for the workplace

3. Before connecting the air pipe, confirm whether the parts of the spray gun are complete and firm

4. It is strictly forbidden to point the tip of the gun to yourself or others to avoid injury caused by misoperation

5. Wear respiratory protection equipment when working (because there will be paint mist when spraying)

Instructions:

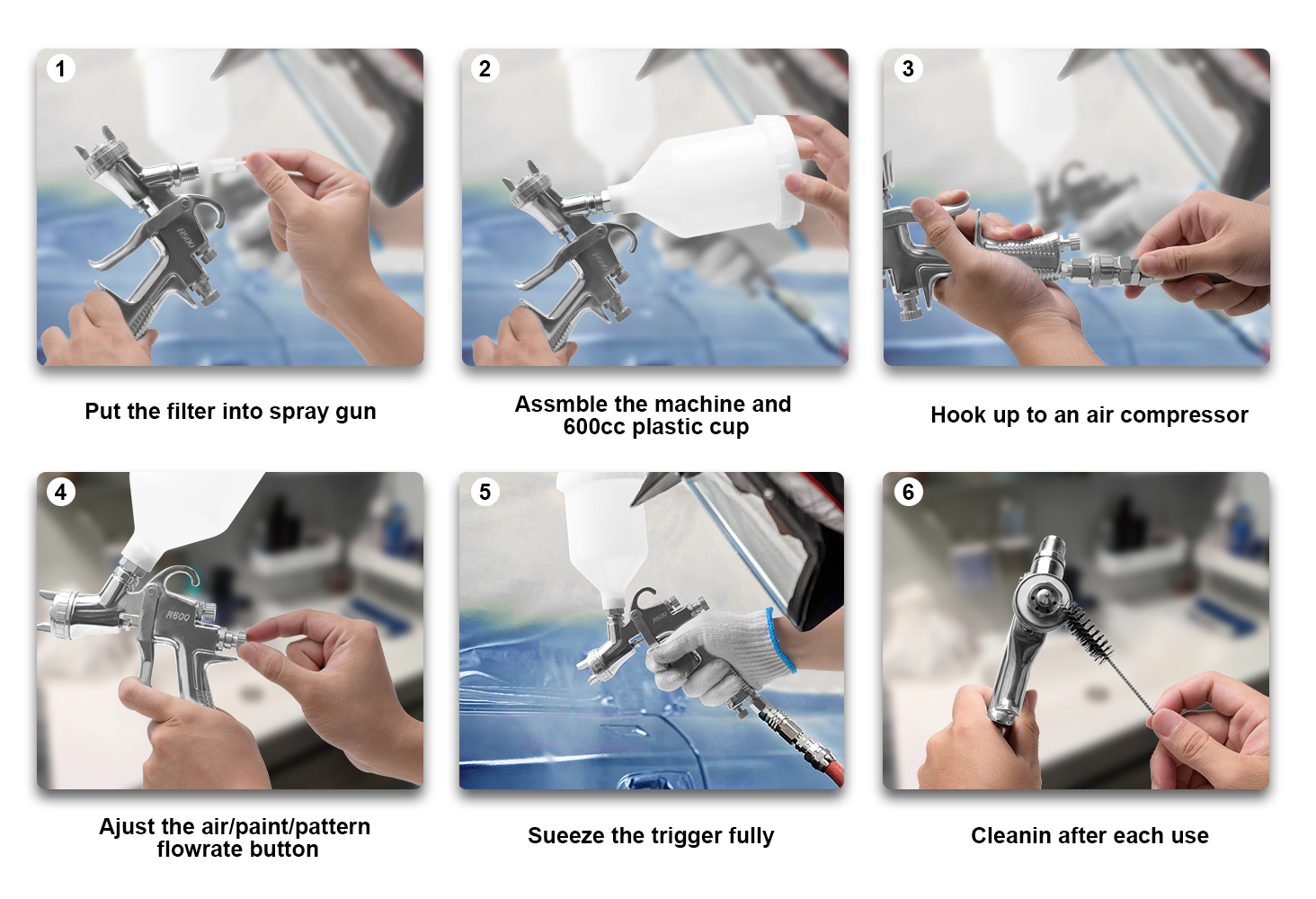

1. Before spraying for the first time, you need to clean the residue in the paint channel, add thinner to the gun pot, and try to filter the inside of the spray gun to ensure cleanliness.

2. Adjust the appropriate spray air pressure when spraying

3. Control the angle and distance between the spray gun and the spray part during spraying

4. Before pre-spraying, after pulling the trigger, the first gear can be used for blowing dust

5. The paint flowing through the nozzle in the second stage is atomized by the pre-spray air at the same time

6. According to the customer’s paint flow, adjust the spice screw plug to control the stroke of the gun needle, and freely adjust the size and flow of the paint

7. According to the customer’s spraying range, adjust the size and width of the atomized spray to achieve a complete spraying effect

8. After use, clean the air flow cap and nozzle in time (first pour out the remaining paint in the gun, and then add the thinner while shaking the spray gun while pulling the trigger as far as possible to let the residual paint inside the spray gun spray out. Then remove the air flow cap For cleaning, if the air cap is too dirty, you need to soak the thinner for a period of time before cleaning. Be careful not to damage the holes on the air cap when cleaning. After removing the air cap, protect the nozzle and avoid damage to the nozzle. Please wash it. Nozzle bumps and air cap hole damage will affect the atomization effect.)

Reviews

There are no reviews yet.