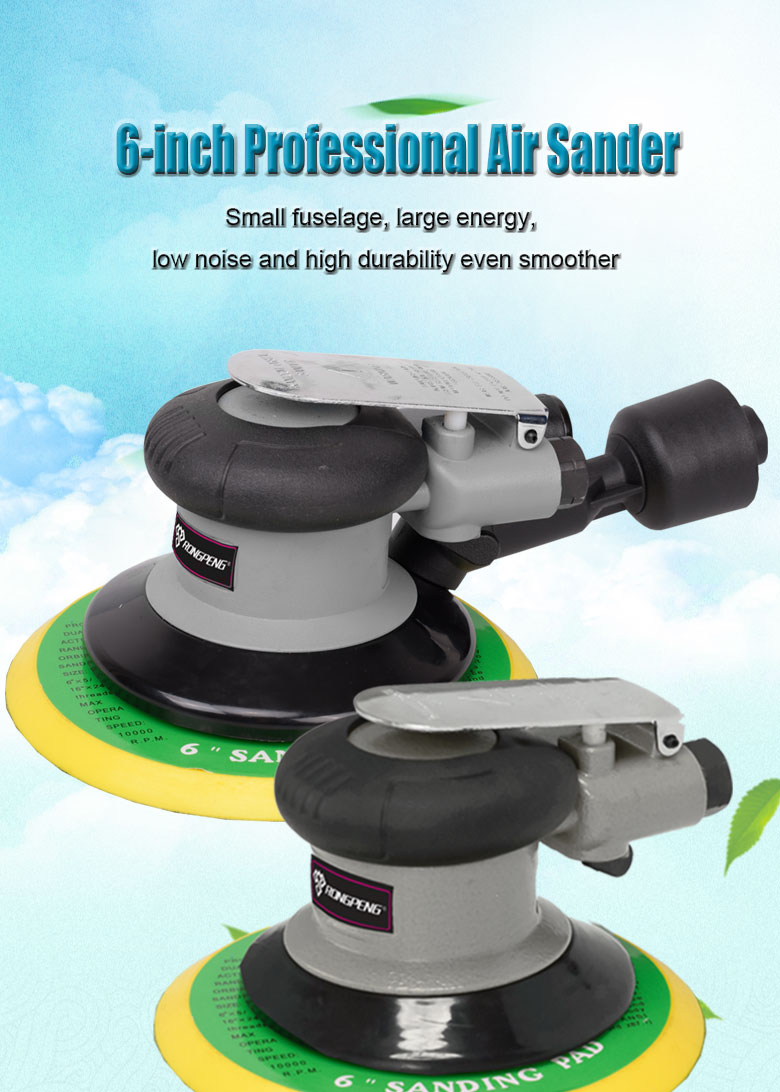

RONGPENG Air Sander with 6 inch pading

Features/ benefits:

- Heat treated eccentric shaft by Ipsen imported from Germany;

- High quality bakelite rotor blade,durable and hard to deformed;

- Industrial bearing,high precision and long working life;

- Light Weight, Low vibration, Low center of gravity design;

- Perfectly Balanced Sanding Pad, Low vibration for swirl-free finishes;

- Best for all kinds vertical and overhead sanding applications,

polisher of welding slag,weld,rust,burs and metal products processing residues.

Application:

- Construction

- Automobile and other fabrication

- Manufacuring and repair industries

- Mold industry

- Woodworking and furniture manufacuring

Technical Parameters :

6″150mm air sander(Rear exhaust)

Free speed Rpm:12,000

Eccentric Drbit:5mm

Air Inlet:1/4″

Air Hose(ID):3/8″

Avg.Air Consumption:4.5 cfm

Sug.Air Comp.((HP):2

Net Weight:0.8kgs

Max working pressure:90PSI

Popular brands in worldwide:

Customer Questions & Answers:

Q1: What’s your MOQ?

A: Our MOQ is 100 units per model for RONGPENG brand.

Q2: What’s your payment terms?

A: We could accept L/C, T/T and Credit card, also accept the payment against B/L copy after discuss detailed.

Q 3: What is the lead time?

A: Sample: 7days, mass production 20-40 days for the first order.

Q 4: Can we put our logo on our products? Is there extra charge for it?

A: Yes, we accept the OEM brand and the different logo way on the housing, stickers are without extra charge,

mould and laser engraving with different cost and we can discuss detailed.

Q 5: Can samples be delivered free charge?

A: For quality reference, we can supply FOC 1-2 samples, but Freight Collect please.

Q6: How about your company scale?

A: our company is with 1400 employee and covers 100,000 square meters, more than 120 engineers and 100QC

for quality control and improvement.

Company Profile:

R&D and Quality Center Team

Q 7: What’s your warranty?

A: our warranty is 12months limited warranty except the easy wearing parts.

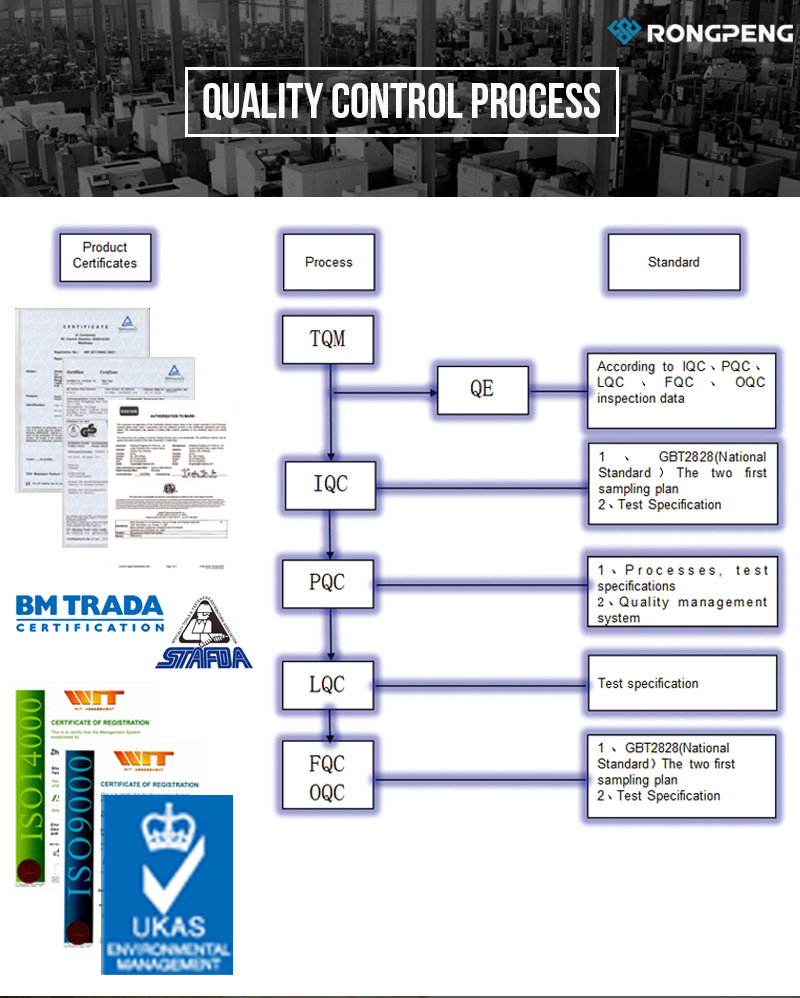

Q 8: What are your QC inspection steps?

· We also have 7 QC steps inspection steps:

· 1. Raw material inspection

· 2. Metal work inspection

· 3. Heat treatment inspection

· 4. Assemble line 100% inspection

· 5. Life inspection test

· 6. Packing inspection

· 7. Final inspection in the warehouse

· So trust us means get more expected

Q 9: What’s your heat-treatment?

A: we are using the Germany Ipsen heat-treatment machine for our key parts which extend the long working life.

Q10: What’s your production capacity?

A: Air tools: 300,000pcs per month, air spray guns 500,000pcs per month, air nailers 300,000pcs per month,

airless sprayers 30,000pcs per month

Q 11: What’s your certification?

A: We have CE/GS/EMC/ETL/UL by TUV Rheinland and SUD, we also pass the BSCI/SA8000/ISO9000.

Reviews

There are no reviews yet.